stationary hub | bace

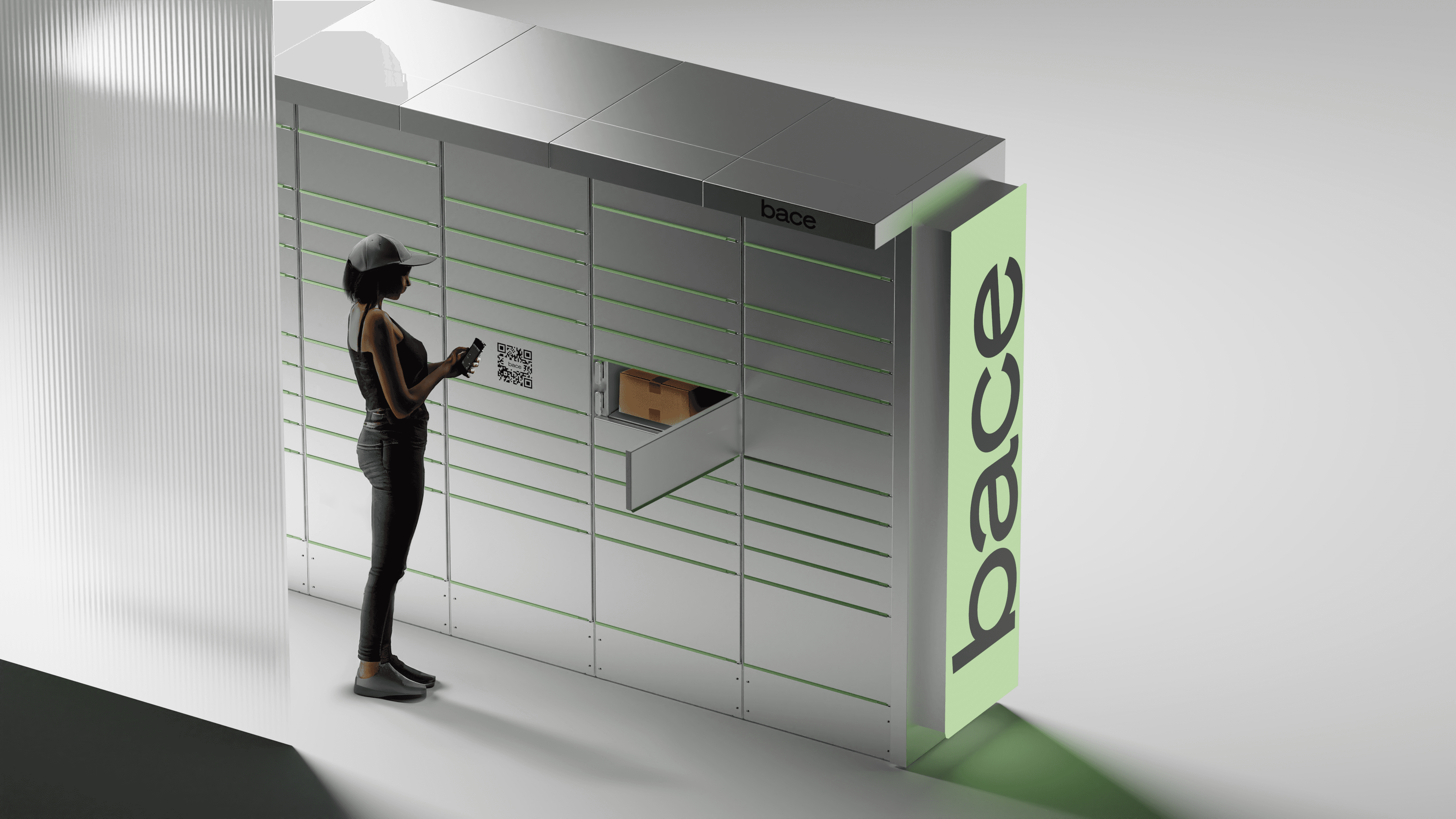

An agnostic locker, for logistics, peer-to-peer swaps, storage and more.

00

problem

Parcel lockers create return on investment through utilisation - every time a door opens/closes the owner earns money. Parcel lockers restricted to a single logistics provider are not fully utilised. Further to this, there are "different" lockers for luggage, returns and even lockers specifically for padel courts! All of thse market inefficiencies create a higher cost, lower utlisation product for the client.

solution

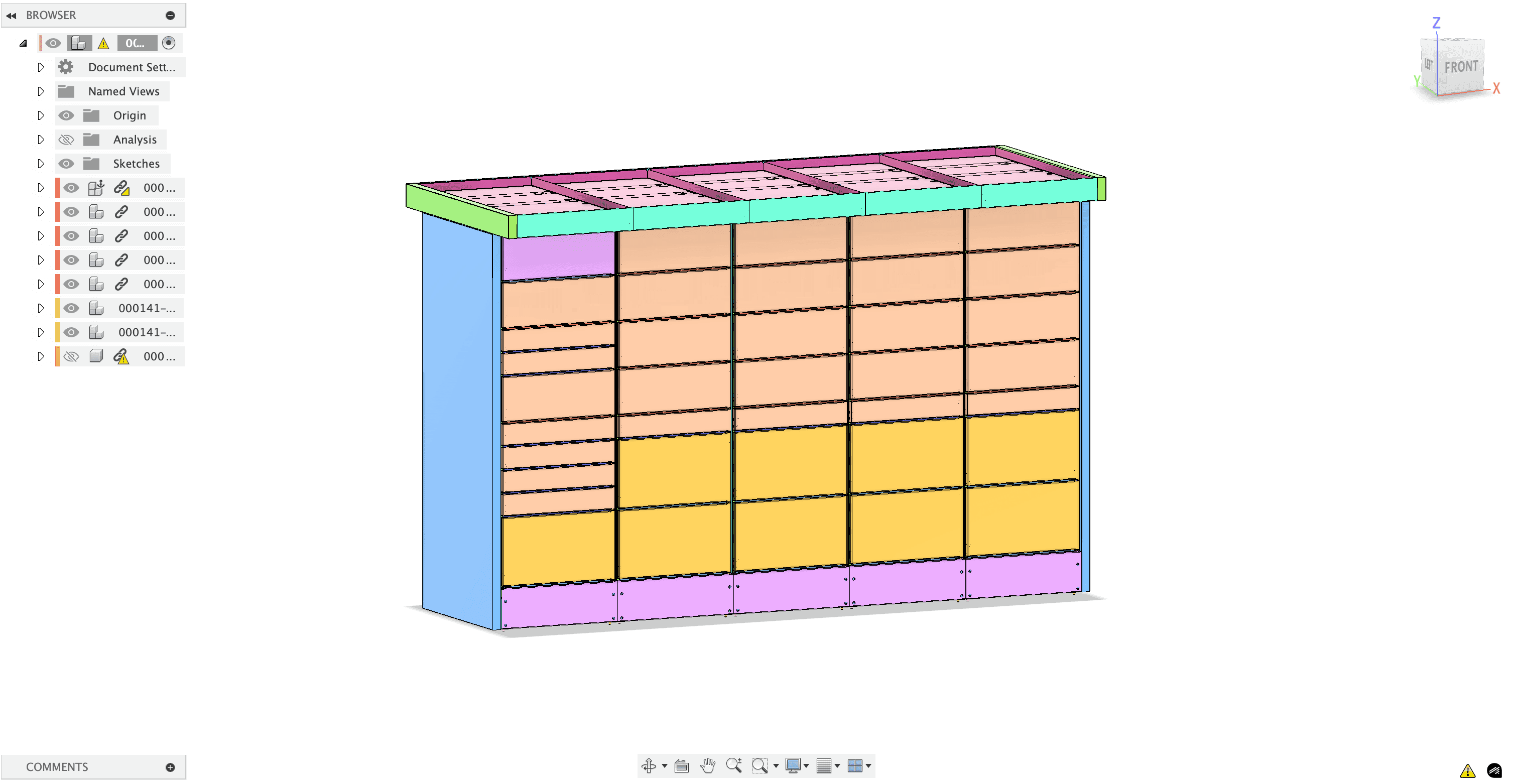

A fully agnostic modular parcel locker. Designed to be truly agnostic — compatible with all major logistics providers and adaptable to multiple use cases. Its modular architecture lets customers configure lockers to their specific requirements without the cost or delay of a bespoke design. This use-case flexibility dramatically shortens return on investment, reducing typical payback periods from 3–5 years to, in some cases, under 12 months.

Joined the project after the MVP stage, taking a one-off prototype and developing it into a fully engineered, production-ready locker. Led mechanical design, supplier coordination, DFMEA, and engineering testing to ensure the system met performance and manufacturability standards. Completed in a startup manor: fast and hands-on.

When I joined the project, market demand for an agnostic parcel locker had already been validated. My role was to take the MVP design, integrate feedback from the pilot, and turn it into a market-ready, manufacturable product. This involved refining the mechanical design, managing an international supply chain with partners in China and Germany, and assembling electronics in-house to accelerate development.

Engineering work focused on product safety, reliability, and long-term performance. Using a DFMEA approach, I identified and managed design risks systematically. Testing combined formal verification with practical, hands-on validation — from certified trials with TÜV SÜD to in-house endurance testing, such as cycling the locker doors 10,000 times to ensure lifetime durability. (Sometimes in a startup you can't afford equipment, so you just have to do it by hand).

I remained hands-on throughout the project, leading and taking part in the first full installation in Dortmund in August. The photos below show our team completing that initial setup. Carrying out the installation ourselves provided invaluable insight into the product’s real-world performance and assembly process. These learnings have directly informed design improvements and are now embedded in the first customer products.

01

02

03

04

see also